PUMA - Pump control

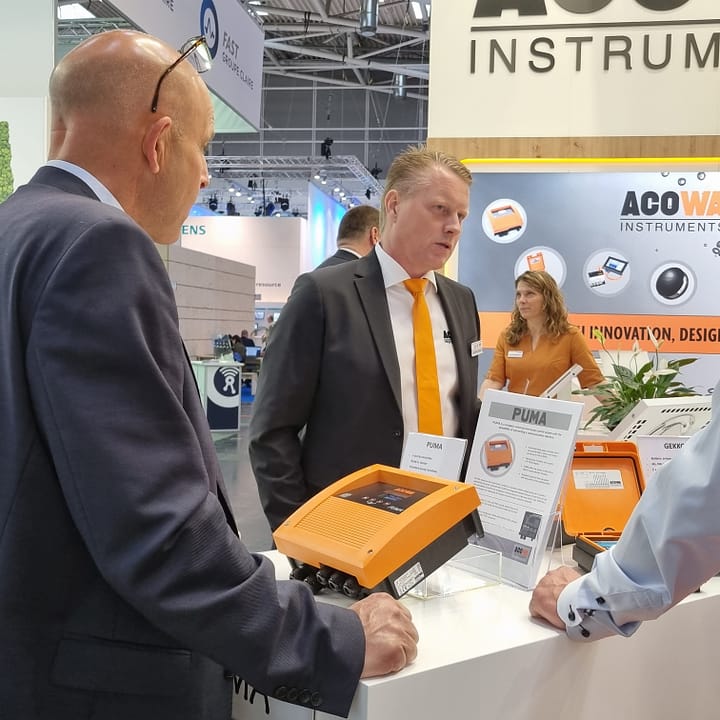

PUMA – Pump Control is a universal compact single-pump controller with the possibility of communication

The PUMA - Pump control operates both 1- & 3-phase pumps

This device is a versatile and compact single-pump controller equipped with communication capabilities. It has the ability to operate both 1-phase and 3-phase pumps, handling currents of up to 12A (5.5KW). The pump controller features a robust two-part, impact-resistant IP65 encapsulated housing, which guarantees durability and protection against harsh environments.

Notably, the PUMA cabinet’s compact size, measuring only 23cm in width, allows for easy mounting on walls, street cabinets, and other enclosures. Its user-friendly design facilitates easy connections using bottom-mounted fittings, screw terminals, as well as spring clamps.

Communication with PUMA - Pump control

Experience versatile choices: As standard, PUMA is delivered without a communication interface. However, you have the option to enhance it with optional LTE-m 4G or NB-IoT modems. Notably, the communication module is designed with easy replacement capabilities to support future IoT requirements.

In terms of security, PUMA utilizes the ModBus TCP/IP protocol, which can be encrypted via TLS. This guarantees the highest standards for secure communication. Impressively, all PUMA registers share the same data type, which streamlines data transmission as it only requires one telegram to get updated data.

Choose how you want PUMA to operate. It can function as a stand-alone unit for direct communication, or integrate seamlessly with AcowaDash. which enables a wide range of protocol types such as REST, API etc.

User interface and visualization with PUMA - Pump control

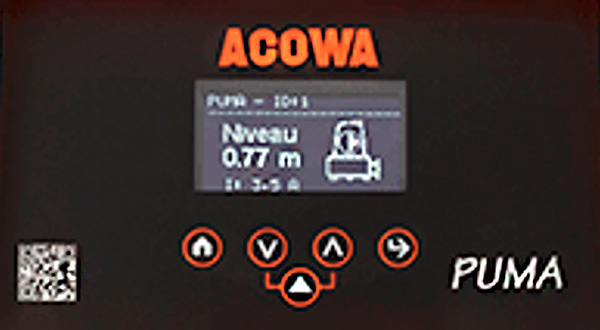

Facilitating seamless daily operation, PUMA is equipped with a 2.4″ OLED display on the front and 4 user-friendly control buttons.

Besides its user-friendly interface, PUMA also offers the advantage of using the free configuration tool, AcowaZoo, for seamless control and visualization. Alternatively, users can opt for AcowaDash, providing even more options for efficient pump control.”

Data Collection with external equipment

The PUMA can basically collect data and log signals of several different types by utilizing external standard 4-20mA / 0-10V DC or standard DI equipment. This feature enhances versatility, making the PUMA an ideal choice for diverse monitoring and logging needs.

Read more about the PUMA - Pump control

Lastly, for more info about the PUMA in a country near you, go to our agents page and connect to: Agents with PUMA

Additionally, for danish speaking people – feel free to visit wasys.dk/puma/

Unique features of PUMA - Pump control

Distinctive features of PUMA pump control include the following points:

- Validated flow calculation, accurately determining the pump’s actual capacity

- Inlet flow calculation, displaying the inlet profile to the pumping station

- Unique current measurement on all 3 phases and phase sequence detection

- Specialized functions for stormflow calculation, daily exercise, daily depth pumping, flushing, and varied starting level

- Built-in powerbank, eliminating the need for an external battery backup in case of power failure

SPECIFICATIONS

Generel specifications for PUMA Pump Control are the following:

| Dimensions | W=237mm x H=248mm x D=98mm |

| Weight | 1350g |

| Wire connection | 0.5 – 6mm2 |

| Vibration (sinusoidal) | 10-500Hz, 1G |

| Free fall drop | 30 cm |

| Enclosure class | IP65 |

| Power supply | 1x230V AC or 3x400V AC +10%/-20% |

| Frequency | 50/60Hz |

| Input power consumption | 0,004 to 0,06A |

| Max. fuse | 16A |

| IK max | 6kA |

| System earth | TT |

| Certificates | CE |

| ENVIRONMENT | |

| Humidity | 10% – 95% non-condensing air |

| Operating temperature | -20°C to +50°C |

| Storage temperatur | -20°C to +60°C |

| Functional altitude | Max. 2000m above sea level |

| PUMP: | |

| Supply voltage | 1-phase 230V AC or 3-phase 400V AC |

| Motor size | Max. 5,5kW |

| Maximum power consumption | 12A |

| Motor protection | 3-phase electronic current measurement |

| Cable/signal length | Max. 10m |

Input and output features for PUMA Pump Control are the following:

| BUILT-IN POWER SUPPLY | ||

|---|---|---|

| Output voltage | 24V DC | |

| Output current | Max 100mA | |

| Tolerance | +/- 20% | |

| ANALOG INPUTS | ||

| Number of analog mA inputs | 1 | |

| Electrically insulated | No | |

| Measuring range | 0/4–20mA | |

| Input impedance | Approx. 100 Ω | |

| Measurement accuracy | Better than 0,5% of FS | |

| Signal range | 0-24mA | |

| Cable/signal length | Max. 100m | |

| DIGITAL INPUTS: | ||

| Number of digital inputs | 2 | |

| Electrically insulated | No | |

| Digital signal | Low < 5V / < 1mA / High > 12V / > 4mA | |

| Signal range (min/max.) | 0–30V DC | |

| Cable/signal length | Max. 100m | |

| DIGITAL OUTPUTS: | ||

| Number of digital outputs | 2 | |

| Electrically insulated | Yes | |

| Insulation voltage | 4 KV | |

| Relay type | Relay outputs | |

| Cable/signal length | Max. 100m | |

| Constant load | max. 2 A @ 230Vac – AC1 max. 100 W @ 230Vac – AC3 max. 1 A @ 30 | |

| Minimum current | 5 mA @ 10 V | |

| Maximum start-up current | 6A @ 20 ms. | |

| Switch speed | Max. 10 Hz |

ACOWA´s PUMA has the following features:

- Advanced single-pump control

- Possibility of either 4G or NB/IOT communication interface with “FAST RESPONS”

- Modbus TCP/IP protocol for communication with AcowaCore or users SCADA/SRO system

- Unique function for current measurement on all 3 phases as well as phase sequence detection.

- Operation via graphic 2.4 ”OLED display

- Validated flow calculation, where the pump’s “true” capacity is calculated

- Inlet flow calculation showing the inlet profile to the pump station

- “Running blind” function via level float switch if the pressure transmitter is faulty.

- Possibility of overflow calculation via AcowaCore

- Function for daily exercise of pump so that it does not get stuck during prolonged downtime

- Function for daily depth pumping, so possibly. floating layers can be avoided

- Possibility of varied starting level, so that fat build-up is avoided

- Configuration of PUMA via AcowaZoo PC software

| Product number | Description |

|---|---|

| 1772-2205000 | PUMA pump control without communication interface |

| 1772-20225042 | PUMA pump control with 4G modem |

| 1772-20225002 | PUMA pump control with NB/IOT modem |

| 1772-20220042 | PUMA 4G modem |

| 1717-20220002 | PUMA NB/IOT modem |

PUMA is used in the following applications:

- Pumping stations